Packaging

In 2021, we continued our focus on packaging – an area of our business where continuous improvement is needed.

We also know this is a complex aspect of our business that has many components, including concerns about the increase of plastic waste in landfills and the oceans, the need for more uniform waste collection programs, the need to increase the recycling infrastructure, the diversity and fragmentation of laws and regulations, and the shortage of viable alternatives that meet our needs. It will take time and the cooperation of many – including our suppliers, members, the packaging industry, municipal services and governments – working together to come up with solutions.

TRADE-OFFS & LIFE-CYCLE ANALYSIS

Trade-offs

Packaging is complex and trade-offs need to be made. We realize the trade-offs in selecting materials, and attempt to balance them and come up with solutions that have an overall positive impact.

There is no perfect package; choices require energy, water, and resources, and create an environmental impact. We consider every aspect of the process, from raw materials extraction, to recycled content, to production and delivery. No matter which material is selected, there are consequences at every stage of the process. By examining these solutions holistically, we make choices based on many factors such as water impacts and greenhouse gases throughout the life cycle of production, delivery, consumption and end of life.

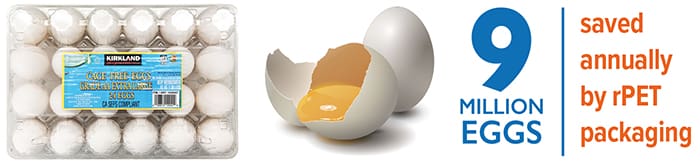

Egg Packaging Trade-offs

While we recognize that recyclability of egg cartons is an increasing challenge for some of our members, we also prioritize reducing food waste in our supply chain. Using this packaging saves 9 million eggs a year from the waste stream. In addition, our egg packaging is made of 100% recycled PET water bottles and is 40% lighter than pulp egg cartons. This weight difference and packaging construction allows for 50% more cartons to be packed onto a truck, reducing the delivery impact between farms and our Greenhouse Gas Emissions (GHG) footprint.

Life-cycle Analysis

In order to better understand trade-offs and to optimize packaging options we utilize Life Cycle Assessment tools that allow us to:

- Understand the greenhouse gas emissions of materials selected

- See the water use and eutrophication of water in the manufacturing process

- Compare the weight and efficiency of truck delivery impacts

- Make more informed decisions by seeing the total impact of packaging production and end-of-life options from extraction to disposal

Global Packaging Plan Overview

In 2019, we introduced our Global Packaging Plan to address many aspects of our business. It is divided into three categories: packaging goals, implementation plan and packaging strategies. Here is an update on our progress for fiscal year 2021.

Packaging Goals

- Reduce our operational packaging waste by improving our efficiencies, with the added benefit of reducing expenses.

- Provide sustainable packaging to our members without compromising food safety, product quality, or sales while ensuring our packaging: (1) complies with laws and regulations, (2) reduces materials, and (3) communicates effectively with our members.

Implementation Plan

Adopt global packaging, recycling and waste strategies for both operations (including operational waste and incoming pallet product packaging waste) and merchandising. Our progress for 2021 includes the following and can be reviewed in more detail on our Waste Minimization page:

- Developed and implemented Standard Operating Procedures for operational packaging waste in U.S. locations

- Launched the iGPS plastic pallet recycling pilot program

- Increased shrink and cardboard recycling in operations by 13.3%, a portion of which comes from incoming pallet packaging of products sold in our locations

Create internal systems to track and monitor our operational packaging waste and packaging footprint. Our progress for 2021 includes:

- Continued our packaging data collection process in an effort to gather accurate, detailed packaging information and develop a clear understanding of our packaging footprint. This project allows us to more closely track our materials use in our packaging choices, determine more effectively where we can make improvements and provide more transparency in the supply chain. With this information, we can make targeted goals based on actual data and make meaningful improvements.

- Made continued improvement to our global operational waste diversion reporting systems

Explore further partnerships to support innovations for packaging and packaging waste. Our progress for 2021 includes:

- Joined and/or became members and participated in numerous packaging organizations which include:

- SPC: Sustainable Packaging Coalition

- How2Recycle label program

- APCO: Australian Packaging Covenant

- APR: Association of Plastics Recyclers

- PAC: Packaging Consortium: Packaging Association of Canada

- Working with materials experts at universities for input and advice

- Partnering with our suppliers to improve packaging. For example, a supplier in the UK, provides a comprehensive packaging option that reduces plastic packaging, uses recycled content, creates recyclable packaging and uses FSC certified fiber. To learn more, please see our U.K. Costco Connection article, Beyond the box.

Packaging Strategies

- Reduce the amount of packaging overall

- Increase the recycled content and certified fiber in packaging

- Increase the recyclability and compostability of packaging

- Educate and learn from employees, suppliers and members the importance of sustainable packaging and recycling

Progress on these are outlined below.

Reduce the amount of Packaging Overall

Importance of Reduction

We recognize the global need to reduce the amount of packaging we use to keep waste out of landfills and to keep plastic out of the oceans. We are committed to doing our part. Our efforts are balanced against protecting the integrity of the product, the availability of suitable alternatives and the complex area of recyclability that is dependent upon geographic areas. In some cases we have eliminated plastic altogether, and if not possible, we try to reduce it through redesign. We also look at ways to reduce paper and corrugated packaging.

Progress to Date – Reduction Efforts

In 2019, we began an internal review to determine our packaging footprint. We determined that we have implemented packaging in the last several years that reduces our plastic footprint by over 8.6 million pounds for fiscal years 2019-20, which is summarized in the 2019-2020 packaging footprint summary.

Costco continues to make progress toward reduction of packaging as we review each item for opportunities to make meaningful changes. Each year brings new progress in our quest to add more items to this initiative. In 2021, we further reduced plastic by over 17 million pounds. We are making strides in this effort, as our year-over-year progress continues to add up and examples of our packaging footprint reduction, based on supplier reports in 2021 include:

- Redesigned our tub for Kirkland Signature™ Platinum Performance UltraShine Dishwasher Detergent Pacs, resulting in 35,000 pounds less plastic annually.

- Changed Kirkland Signature™Ultra Clean HE Laundry Detergent Pacs from a tub to a bag, reducing plastic use by 1.36 million pounds annually.

- Changed the fresh apple packaging in our U.S. produce department from plastic clamshells to corrugated boxes, reducing plastic use by 11.3 million pounds annually.

- Reduced the gauge in our U.S. fresh meat trays by 25%, lowering our plastic use by 1.4 million pounds annually.

- Changed Kirkland Signature Roasted & Salted Cashews from a jar to a bag, reducing our annual plastic use by 1.6 million pounds.

- Reduced the gauge in our fresh meat roll bags in the U.S., resulting in less plastic usage by 500,000 pounds annually.

- Changed wine bottles from glass to bag-in-a-box solutions, reducing the annual materials weight by over 2 million pounds.

- Changed the film window on our Kirkland Signature Triple Cheese Tart in Korea to a wood-based cellulose plastic that is also SFI certified.

- Converted loaf packaging the bakery to paperboard boxes.

- Reduced plastic packaging by our produce suppliers by over 295,000 pounds in the U.S. and Mexico.

- Changed the packaging on two service deli items, resulting in a 300,000 pound reduction in plastic in Australia.

- Replaced two black plastic bakery trays with fiber-based solutions, replacing plastic use by over 300,000 pounds annually in Canada.

- Discontinued individually wrapping Kirkland Signature apparel shipments in plastic bags.

In addition, our branded partners across the globe have made many efforts to change their packaging to align with our goals to reduce packaging, increase recycled content, and improve recyclability and communication with our members.

We continue to review and test items for further opportunities to reduce plastic and other materials. While the pace of change may appear slow, it can take several years to scale the changes, review and test to ensure packaging changes don’t result in product damage or food spoilage – which could be environmentally worse than the packaging impact.

INCREASE THE RECYCLED CONTENT & CERTIFIED FIBER IN PACKAGING

Importance of Recycled Content

Our goal is for packaging to be widely recyclable and/or made from recycled content. Using recycled content serves many purposes:

- It supports the recycling industry, which we need to help us to manage the current state of packaging waste. While recycling has suffered from an outdated infrastructure, it is still a viable solution and an industry worth supporting. We will not be able to address our plastic waste issues without supporting the recycling industry. It supports the circular economy, and provides opportunities for closed-loop systems that regenerate materials.

- Depending upon whether the recycled content is fiber or plastic, recycling may reduce energy use in the production of packaging by lowering greenhouse gas emissions. The procurement of raw materials has an energy footprint that can be reduced by recycling existing materials, which is less carbon-intensive. Additionally, recycling diverts materials from landfills, which reduces methane emissions from materials in landfills.

Importance of Certified Fiber-based & Corrugated Packaging

Whenever possible, fiber used for paper-based packaging should come from known sources, should be procured from well-managed forests and should not contribute to deforestation. We want our fiber-based packaging sourced from responsibly managed and certified forests and/or use recycled content and alternative fibers when feasible. Costco currently accepts forest management certifications from three leading organizations: Forest Stewardship Council (FSC), Sustainable Forestry Initiative (SFI) or Programme for the Endorsement of Forest Certification (PEFC), with a preference for FSC. We support certified fiber and traceability in fiber and paper resources

More information about Costco’s deforestation goals can be found on the Environmental Impacts and Land Stewardship page.

Progress to Date - Recycled Content

Our use of recycled content in plastic packaging continues to be on par or ahead of global targets set by the many regions in which we operate. Costco has been an active user of recycled content in plastic packaging for many years and continues to increase its use of recycled content. Our use of recycled fiber also continues to grow. Please view a summary on our previous 2019-2020 increase of recycled content. In FY20, all of our U.S. Ecommerce shipping boxes fulfilled by Costco used 100% recycled content. In FY21, due to increased demand for ecommerce products and supply constraints, we had to supplement some boxes that did not utilize 100% recycled content. Examples of our progress on recycled content and certified fiber use in 2021 include:

- U.S. Kirkland Signature™ spice clear bottles use 50% recycled content.

- Kirkland Signature pet food bags increased from 30% to 50% recycled content.

- Australian fresh oyster tray packaging is now 100% recycled content.

- U.S. Kirkland Signature Ultra Clean HE Plant-Based Liquid Laundry Detergent packaging is composed of 80% post-consumer recycled content and 17% plant-based materials.

- U.S. Roll stock bags for fresh meat now contain 60% post-consumer recycled content.

- U.S. fresh produce corrugated apple boxes are FSC or SFI certified.

- U.S. fresh produce molded fiber baskets for mushrooms are FSC certified.

- U.S. food court plates are SFI certified and USDA Biobased certified.

- Our Kirkland Signature apparel packaging, hang tags, paper tags, paperboard inserts and polybags are all 100% recycled content.

- In Australia, our service deli replaced the black plastic base for rotisserie items and salads with recycled content and recyclable clear base packaging.

An additional 26 items globally now use recycled content and we continue to increase the items that are packaged with certified fiber materials.

INCREASE THE RECYCLABILITY & COMPOSTABILITY OF ALL PACKAGING

The Importance of Recyclability – and the Challenges

In the past several years, recycling and recyclable packaging have received a lot of attention. We understand that inconsistencies in the recycling process and service levels from place to place have contributed to confusion and distrust in the viability of recycling.

Many members and the general public were surprised to learn that recycling, at least in the U.S. and Mexico, is typically a private enterprise, and not a public service. In Canada, extended producer responsibility is mandated by regulations where curbside “blue box” programs are offered to the majority of the population and run by public and/or private enterprise, and paid for by the consumer and/or retailer. This means recycling is also dependent on market forces.

On January 1, 2018, global market forces were severely impacted when China banned the import of plastics for recycling, which accounted for 70% of global recycling, turning a revenue stream to an added cost for many global recyclers. Those items that recycling services can sell for materials recovery are what gets collected. If they cannot sell the used packaging, those items end up in the landfill and are suspended from collection. For recycling to improve, investment in recycling businesses and infrastructure is needed.

To be considered “recyclable,” various rules, regulations and guidelines require that the product be “widely recyclable,” meaning at least 50% (or more depending upon the geographic area) of the population has access to recycle the packaging. We also recognize widely recyclable packaging is dependent upon the availability of recycling infrastructure streams, which are inconsistent. This underscores the need for a multifaceted approach to recyclability.

Designing recyclable packaging is critical to creating a supply of recycled materials. We also want to provide an opportunity for our members to recycle by providing them with responsible choices in our packaging solutions. Recycling promotes a circular process where materials can be used more than once before reaching the end of life.

To assist us on our path to make our packaging recyclable, this year Costco joined the Association of Plastics Recyclers (APR), to support and learn how to improve recycling of our items, to support the industry that is a key driver of recovery of materials and to work toward meeting global requirements.

Additionally, our membership in the Sustainable Packaging Coalition and expansion of the How2Recycle® label on our packaging, helps us to analyze the recyclability of a package and communicate the proper sortation to our members.

Progress to Date - Recyclability

We continue to make progress in increasing our recyclable packaging. Many of our packages have been recyclable for some time. Please view our previous 2019 - 2020 increase of recyclable content summary. Examples of our progress in 2021 include:

- In the U.S. the majority of our fresh apple clamshells have been converted into recyclable corrugated packaging.

- In Japan, our service deli changed the black plastic tray previously used for fresh sushi packaging to a clear, recyclable tray.

Operational Packaging

Costco also recycles a great deal of packaging in our daily operations and diverts over a half million tons of packaging annually. This was an increase of 13.3% in 2021 from 2020. Please see our Waste Minimization page.

Polystyrene

Costco continues to work on developing solutions to address expanded polystyrene use in a variety of packaging types. Some of our 2021 improvements include:

- In some U.S. markets we are now use recyclable PET trays for fresh meat.

- In our U.S. Business Delivery cold-chain packaging we use a dissolvable, starch-based foam with a recyclable film wrap for food product shipping.

Additionally, our global in-house operation recycled over 1,000 tons of Styrofoam® products in 2021.

Food Court Pizza Box

In 2020, the Recycling Partnership commissioned a study to determine the recyclability of pizza boxes. The research found that even moderate amounts of grease on the packaging still allowed for recycling.

Therefore in 2021, we added the How2Recycle® label to our food court pizza boxes to communicate this to our members. While not all recycling programs currently accept pizza boxes, this research supports reevaluating that position.

Importance of Compostability

Costco continues to expand the use of compostable packaging. We also recognize that single-use plastic is a worldwide concern and are exploring opportunities to replace those items with alternative materials. Additionally, we understand that access to industrial composting is limited for our members. With that in mind, we have determined that locations where we have control of the wastes are the best opportunity to ensure that these items get composted. We continue to make progress in our food court packaging globally and actively seek solutions for the remaining food service items to help reduce single-use plastic.

The past year Covid-19 affected many supply chains including those for compostable packaging. While every effort was made to adhere to our goal of compostable packaging for our food courts globally, periodically we were unable to meet that standard due to material shortages.

Progress to Date - Compostability

We continue to review and test available options across the company for opportunities to replace challenging materials. In 2021 we continued to expand and implement compostable food service packaging, which includes compostable birch flatware in our Australian food courts. Please review our 2019-2020 expansion of compostability summary.

Educate

In 2021 we continued to expand our platform for educating employees, suppliers, and members on our packaging efforts and how they can be involved. Additionally, we continue to reach out to learn more about the impact of our choices and making informed decisions.

We accomplish this in a variety of ways:

- Improved package labeling for recycling, recoverability and compostability

- Added the How2Recycle label to over 100 items with another 146 items currently in progress.

- Communication and education to our employees and members in the form of:

- Packaging guidelines for our suppliers and employees

- Internal training courses on sustainable packaging initiatives

- Articles in our company publication, the Costco Connection

- Articles in our employee publication, Costco Today

- Employee club engagement, including activities and guest speakers

- Special projects and internal teams to drive reporting, and to share ideas and solutions

- Direct member engagement through phone and electronic communication

- Package labeling and sustainability certifications

INNOVATION, REDESIGN & OPERATIONAL EFFICIENCIES

Costco continues to look for ways to improve the design of its packaging to reduce the amount, improve the efficiency, and improve operational efficiencies in order to reduce the packaging footprint and reduce costs. Some examples include:

- Costco has always sold goods directly out of the boxes they are shipped in, then reused those same recyclable boxes at the register by offering them to members in lieu of shopping bags. Boxes that don’t get used by members are recycled in-house. More information can be found on the Waste Minimization page.

- We support the redesign of packaging to utilize more efficient pallet configurations, and to reduce the number of pallets and trucks on the road.

- Multiple square jar projects have been implemented to promote this strategy, including the Kirkland Signature™ milk bottle program, candy and nut packaging, and multiple branded partners that have reconfigured their packaging for improved efficiency.

- Redesigned our tub for Kirkland Signature™ Platinum Performance UltraShine Dishwasher Detergent Pacs, resulting in more units per pallet, reducing 51 truckloads annually.

- Moved Kirkland Signature Cashews from a jar to a pouch, resulting in fewer pallets per truck needed to deliver goods as well as a reduction of over 200 truckloads annually.

- Converted some Kirkland Signature wine items into bag-in-a-box solutions, greatly reducing the weight of product on the truck and saving on greenhouse gas emissions.

- Begun testing reusable shipping crates for meat deliveries to their locations in our Spain fresh meat departments.

Closed-loop Success Stories

We work with many suppliers to review and test opportunities to try new materials, design options, and diversion opportunities.

- In Canada, our supplier Ice River collects water bottles, processes them into recycled content for Kirkland Signature Water bottles sold in Canada and uses the remaining material for outdoor furniture.

- In Canada, Costco recycles corrugated shippers and trays with Cascades, which converts them into new packaging products. Some of these products find their way back into Costco warehouses, either directly as Costco branded products or as national branded products. Once their useful life is over, these corrugated shippers and trays go back into the loop and are recycled again by Cascades. More information can be found in this Closed Loop Summary.

Dozens of tests across our regions and product categories are currently being conducted to determine new and innovative solutions to existing packaging issues, to improve recyclability, to replace problematic materials, and to reduce material usage. As these items come online for full utilization, we will continue to report them here.

ADDITIONAL CONSIDERATIONS & FAQs

Material health in packaging is reviewed by our Quality Assurance department. For detailed information on our testing and screening process, please visit our Chemical Management page.

FAQs: Frequently asked questions

We receive many letters and inquiries from our members, who have great questions about packaging. For more information, please review our Packaging FAQ Sheet.